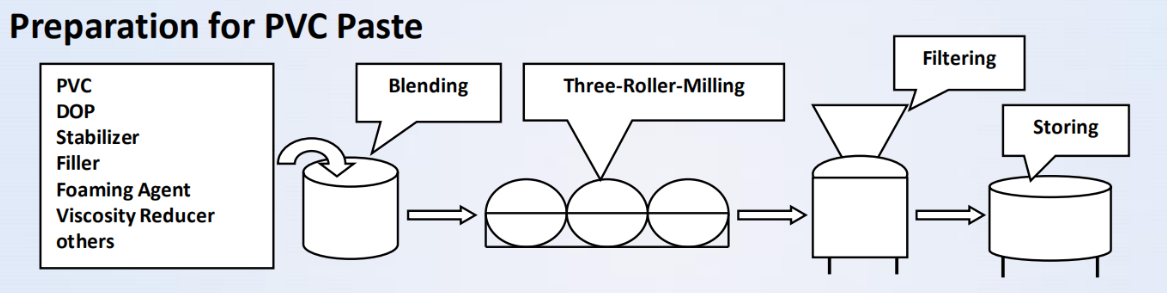

Compound of Print paste and the Functions of every elements

Print paste is a kind of mixture which is compounded of various chemical materials. Print paste is often consists of PVC, DOP, calcium carbonate, titanium white powder, stabilizer, viscosity breaking agent, foaming agent, brightening agent and another agents.

• PVC(CH2CHCL)

Stands for poly-vinyl-chloride. It is a kind of white powder without smells, which has a relative stable prosperity and can not be resolved in water. Once the PVC powder get into the human bodies, it can impact eyes and respiratory tract. So it is essential to protect eyes and mouth and noses by using.

• DOP

Stands for Dioctyl-Phthalate, it is a kind of plasticizer with a transparent of light-colored oily aqueous property. DOP can give products certain compliance when added into the plastic. The more DOP added, the softer the products become. DOP is treated as a important adjuvant for print paste.

• Stabilizer

Because of the decomposition and the dehydrochlorinational reaction with UV-light and heat by processing, the stabilizer needs to be added to prevent this situation, which is usually potassium-zinc-stabilizer.

• Titanium white powder

Titanium white powder is made from titanium dioxide(TiO2). This is a kind of white pigment which can be divided into type R and type A. Among the white pigments has titanium white powder the strongest tinting strength and covering power. With a very stable chemical structure and properties of light and heat resistance, this kind of poison-and smell-free pigment can be widely used in compound of print paste. The type A titanium white powder has a blue color tone with high property of whiteness and dispersity.

• Calcium carbonate

A common used filler to increase thevolume and reduce the cost because of its guaranteed quality and flexible accessibility. Heavy calcium carbonate is produced by grinding and screening while light calcium carbonate is produced by burning, hydrating, carbonizing and drying accordingly. Except the filling ability, calcium carbonate has also functions of heat compensation and stabling.

• Foaming agents

For foaming agent is the azoformamide (ADCA) firstly used because of its highly resolving temperature requirement (190-205 degrees Celsius) in case of foaming in advance. This agent is appropriately suitable for PVC because the PVC-Coat can be foamed in certain by adding the foaming agent in order to increase the coverage and therefore the coat can be easily embossed.

• Epoxidized soybean oil

This agent is unsaturated aliphatic ester from glycerine which is produced from oxidized soybean oil. Epoxidized soybean oil can be used as the plasticilizer and thermo- stabilizer of PVC because of the good thermo- and optical stabilization and splendid water- and oil resistance. SO it can give the products better mechanic strength.

• Viscosity breaking agent

Usually is the MGS-9301 be used as viscosity breaking agent. By compounding is the special solvent oil D-80 available for adjustment of viscosity.