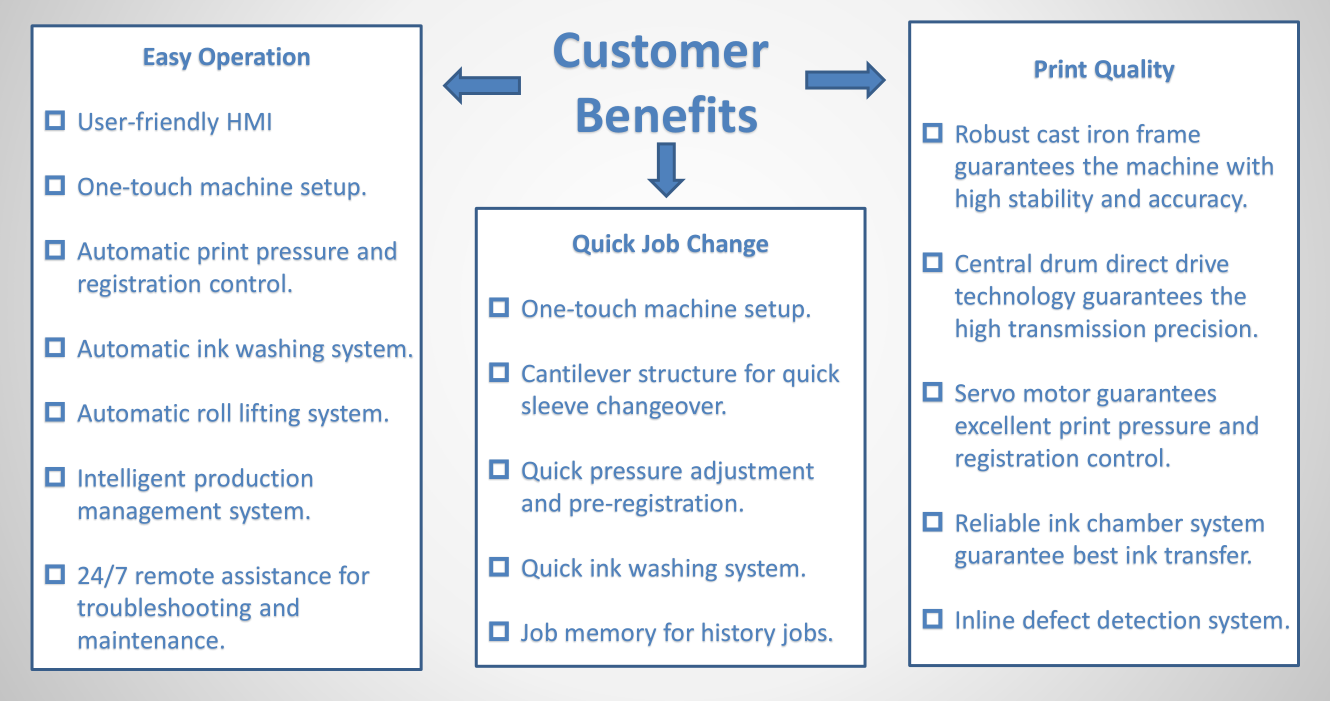

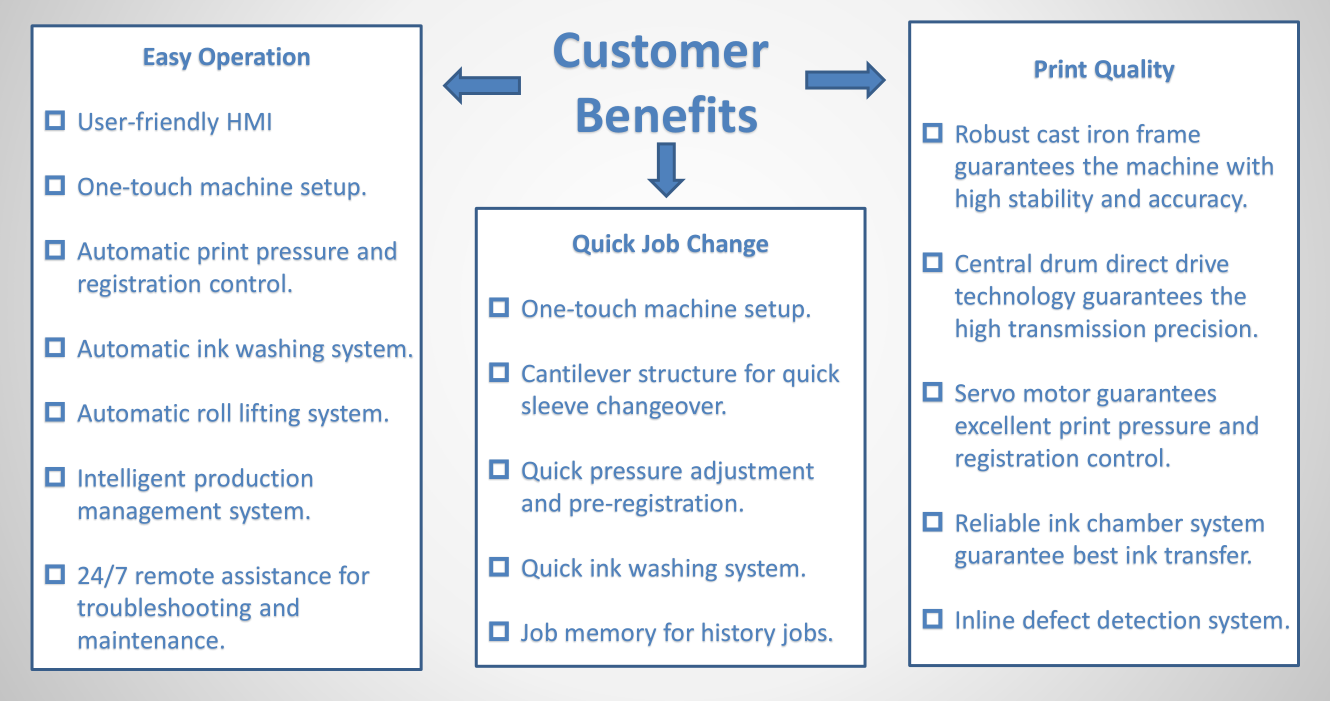

With more than 20 installations, Huayang new model Cinova has attracted the attentions from the printing & packaging industry. Asking by many curious customers, we would like to sum up the main smart functions of Cinova and see how it benefits our valuable customer.

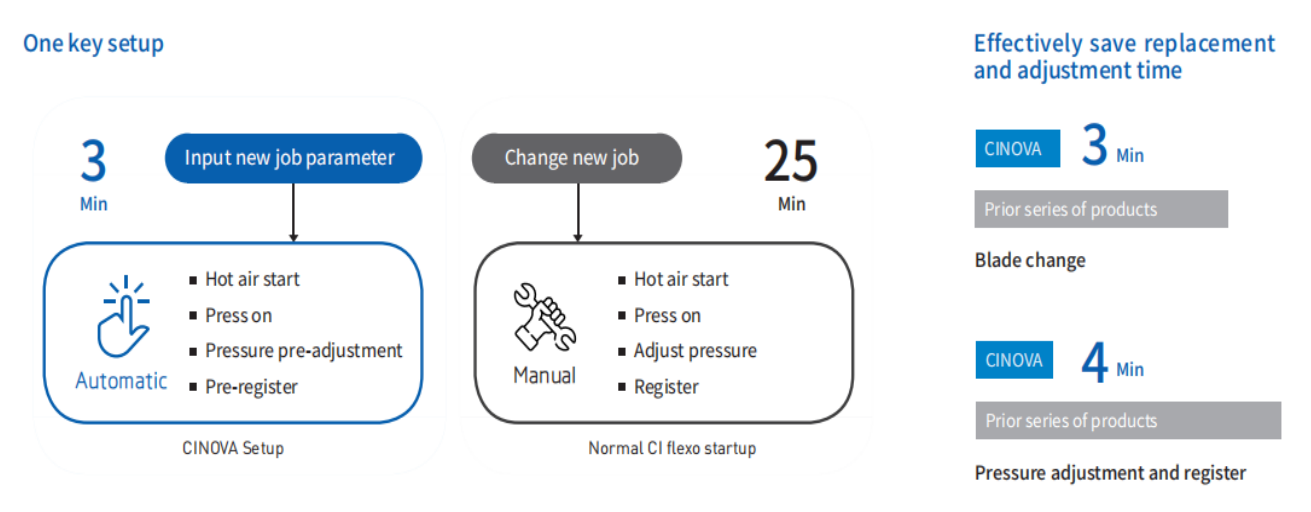

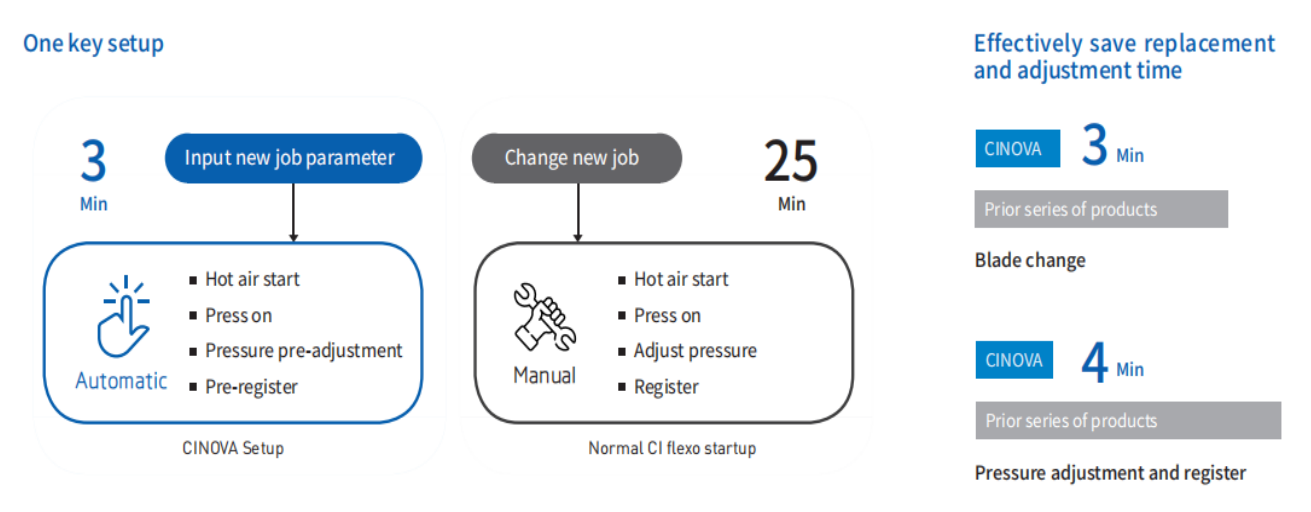

One key setup

This function is target to reduce the start up time and material waste. It works as follows:

Before starting up the machine, input the printing length and press Start button. Then the printing machine will automatically move to specified printing position and achieve precise registration. Only with slight adjustment, the machine is able to print perfect jobs.

Before starting up the machine, input the printing length and press Start button. Then the printing machine will automatically move to specified printing position and achieve precise registration. Only with slight adjustment, the machine is able to print perfect jobs.

Printing pressure automatic compensation

This function is target to maintain a stable printing pressure during machine acceleration or deacceleration. It works as follows:

When machine accelerates or deaccelerates, printing pressure (position) may have slight fluctuation, thus affecting the printing quality. The printing machine will automatically compensate the printing pressure, thus ensuring a stable printing result.

When machine accelerates or deaccelerates, printing pressure (position) may have slight fluctuation, thus affecting the printing quality. The printing machine will automatically compensate the printing pressure, thus ensuring a stable printing result.

Speed self-adaption control function

This function is target to adapt the speed between printing roller and anilox roller during high pressure printing. It works as follows:

In some high-pressure printing, slight speed differences may occur between printing roller and anilox roller. In this case, substrate may become slippery from printing roller, causing ink bars. During 360°rotation of print roller and anilox roller, the servo drive system allows the machine to record and compare the torque, thus automatically optimizing and matching running speed of each color, reducing ink bars.

In some high-pressure printing, slight speed differences may occur between printing roller and anilox roller. In this case, substrate may become slippery from printing roller, causing ink bars. During 360°rotation of print roller and anilox roller, the servo drive system allows the machine to record and compare the torque, thus automatically optimizing and matching running speed of each color, reducing ink bars.

Mandrel constant temperature control

This function is target to maintain a stable temperature of mandrels in printing unit. It works as follows:

It is likely to happen that the printing mandrels accumulates heat during high-speed running. If the heat transfer to printing sleeve and plate, it will cause large dot and dry plate. The Cinova is designed with special mandrel structure to prevent it from overheating. Meanwhile, the mandrel is equipped with cooling system to ensure the mandrel maintain a stable temperature range.

It is likely to happen that the printing mandrels accumulates heat during high-speed running. If the heat transfer to printing sleeve and plate, it will cause large dot and dry plate. The Cinova is designed with special mandrel structure to prevent it from overheating. Meanwhile, the mandrel is equipped with cooling system to ensure the mandrel maintain a stable temperature range.

Fault correction function

This function is target to ensure a safe machine running in case of wrong operation. It works as follows:

If operator input the wrong printing parameters, it may damage the plate. If the position (pressure) motors do not move synchronously, it may twist and damage the mandrel. The torque protection function will prevent machine from damages if there is a mis-operation. During setting of the print repeat and pressure setting, the system will give feedback of motor status and generate the alarm information to avoid the harm to machine and operator incurred by mis-operation.

If operator input the wrong printing parameters, it may damage the plate. If the position (pressure) motors do not move synchronously, it may twist and damage the mandrel. The torque protection function will prevent machine from damages if there is a mis-operation. During setting of the print repeat and pressure setting, the system will give feedback of motor status and generate the alarm information to avoid the harm to machine and operator incurred by mis-operation.